Powder Coating

Flawless Finishes with Professional Powder Coating Solutions

Achieve superior protection and an impeccable finish with our professional powder coating services. At MS Automations LTD, we use high-quality powders and precision techniques to ensure a durable, smooth, and attractive coating for your metal products. Whether for functional or aesthetic purposes, our powder coating enhances resistance to corrosion, wear, and fading—perfect for both indoor and outdoor applications.

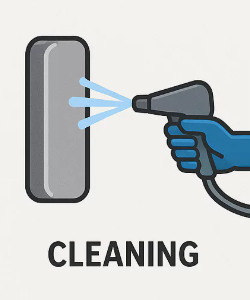

Surface Preparation

The component is cleaned through blasting or chemical pretreatment. This removes contaminants like rust or oils and promotes optimal powder adhesion.

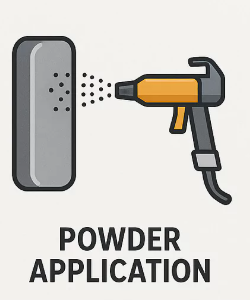

Electrostatic Powder Application

A spray gun charges the powder negatively. The grounded metal attracts the particles, creating a uniform powder layer via electrostatic force.

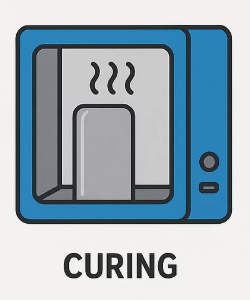

Curing in Oven

Components enter a curing oven at 160–200°C. Heat melts the powder, fusing it into a smooth, hardened coating.

Cooling & Handling

After curing, the part cools to ambient temperature. The final finish is smooth, resistant to corrosion, and suitable for indoor and outdoor use.

How We Work

01

Consultation

We begin by understanding your needs through a detailed consultation. This step allows us to assess your space, discuss your vision, and offer expert advice tailored to your specific requirements.

03

Fabrication

Using high-quality materials and advanced equipment, we bring the design to life with precision. Our skilled craftsmen ensure durability, accuracy, and a flawless finish in every piece.

02

Design Planning

Our team develops a customised design that aligns with your preferences and property style. We ensure functionality, aesthetics, and compliance with safety standards throughout the planning stage.

04

Installation

Our experienced installers carry out the final installation with efficiency and care. We guarantee a secure fit and polished look, leaving you with a result that exceeds expectations.

What You Will Get

- Thickness Testing: Uses magnetic or eddy current gauges. Variability by surface shape requires average-based evaluations.

- Gloss and Color Uniformity: Must match Qualicoat standards when inspected at 3–5 metre distances.

- Corrosion Testing: Includes accelerated salt spray methods to simulate environmental exposure.